Impacts of plastics:

Everywhere we are using the plastics in our routine work, like, from the beginning of the day to the last end. We cannot image the world without plastics, because, it is playing a vital role. Since, the weight of the object is very less, it is extremely easy to carry anywhere in our hand. This will be one of the comfy advantages and it will pop up first in our mind. Another more benefit is that it is recyclable and so, we can reuse it again in any form. The Plastic injection molder is just a device to fabricate the plastics in the desired form.

Classification of Plastics based on Chemical Structure:

Usually, the plastics will be classified based on their chemical structure of the polymer and the side chains. Few of the familiar classifications are silicones, halogenated plastics, polyurethanes, polyesters, and the acrylics. It is also be categorize by the chemical terms like the poly addition, cross linking and the condensation. This is sorted by the chemical participation in the synthesis process. Similarly, we can classify the above terms, with respect to the breakable and the unbreakable things. The unbreakable things have to be recycled again and again and it will never be added in the biodegradable list. The breakable things can be left to decompose in the soil. The plastic injection device will be used to craft the plastic powder in to a beautiful plastic product.

Plastic preparation through Injection Molding:

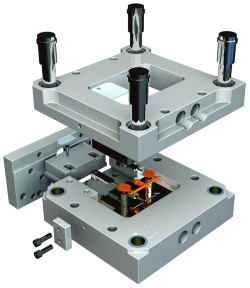

Initially, the plastic granules will be molded, by pouring the plastic powder in the Injection molding machine container. The device will blow certain tolerable heat on the plastic powder. The powder will then be turned out to move in to the screw threads, where, it will move in the liquid form. In the last session, the required design will be set and the semi solid moldable powder will be allowed to stay in the design for a while. After certain minutes, the required product will be moved out for our focus. This is the actual injection molding process, but, contemporarily, we have implemented several techniques with respect to the current trend and have reduced human work, in turn to let them settle in the comfy zone.

Sometimes, the product will be coming out, without fulfilling our requirement and so we need to give finish touch to the product in turn to obtain the desire shape. However, the plastic molding machine will never give the exact shape and so we have to work out further for obtaining the exact shape. Therefore, the finishing of the product will just require four steps and those are clamping, injection, cooling, and ejection. All the above mentioned four steps will just few minutes to achieve the target. Hence, we need not to look over for long time.

The Plastic Molding Machine is availing on online and in the present days, several familiar industries existing to produce the desired shape and structure as like we required. The machines will offer fast performance to acquire the desired shape and structure. Some kind of machines will proffer multiple injection stages. You can get more about molding machines browsing through Google.com.

2 comments:

Well-known makers and traders of plastic granules. Our gamut of wares comprises of HIPS granules, ABS granules and PP plastic granules.

I beyond doubt appreciate your articles and blogs

click here

Post a Comment