The machine of plastic injection molding has literally modernized the easy and quick fabrication of plastic items in number of industries. These industries use anything that made via this method daily; from the comb that they use on the hair to the dashboard on the vehicle that they ride from home. It might be without amplification that the chances for the benefit of this tool are really boundless. Here is a fast notification of how a plastic injection molding machine runs along with certain applications for it people might not have consider of.

Working of plastic injection Molder:

A pattern for a brand is managed and a metal cover is made and fixed to the tool. Plastic thing is attached into a warmed barrel then driven into the mold hole. When it is full, the product and mold cool and the product is busted out. This method is super-fast and effective one, permitting for the mass creation of personalized plastic products with a low essential sum of worker handling.

Standard Application for a plastic Injection machine:

There are some common application are available for a plastic molding machine. If people have kids at home, people can be assure that an injection tool used to make virtually all of their dolls solid plastic divisions. The technology is used for bottle caps in plastic and other kinds of ease packing helps in the food industry. The medical tool area uses it to create knee braces; heart pumps spare parts, fetal heart rate displays, and much more. It is necessary to the making of automotive and aerospace parts, computer electronic devices and kitchen gadgets.

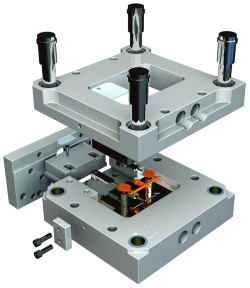

Elements of the injection molding tool:

Injection molding machine changes rough raw plastic into last molded sections via the benefit of inject, melt, cool cycle and pack for thermoplastics. An initial injection molding machine is normally made of these following: mold system, control system, hydraulic system, injection system, and clamping system. The shot size and clamping tonnage are either used in knowing the width of the thermoplastics in injection molding machine, which is the primary element in the entire process. Other reflections have pressure, mold thickness, injection rate, screw design and coldness between tie bars.

Machine function:

Injection molding machine might be divided into 3 types, they are tight-tolerance/precision machines, purpose machines, general purpose machine and high-speed light-wall machines. These types need auxiliary tools to operate. These support tools includes material handling equipment, dryers, mold temperature, granulator and part handling equipment, chillers and more.

Several manufacturing companies specialized in high quality injection molding, but all are not similar. An Ideal one will be more flexible, fast, and client driven both for small and large quantities. Plastic molding machine can be used in any type of electronic devices.

It is a right concept to select firms that are quick, customer-driven and elastic, particularly if people want huge amounts and rapid turnaround or concentrated small volume works. Select firms that have modern plastic injection molding services and tools that vary in weight from 75 to 45 tons.